How Much Does It Cost to Make a LEGO 2026

Podíl

As someone deeply fascinated by both the intricate engineering of toys and the business that powers one of the most iconic brands in the world, I’ve often wondered: how much does it cost to make a LEGO brick? The question is deceptively simple—LEGO bricks are ubiquitous, tiny plastic pieces that spark creativity from children to adults around the globe, but their production is a marvel of precision, sustainability, and high-tech manufacturing. Through my research, which draws on the very latest updates from LEGO’s global manufacturing and sustainability efforts, I offer an authoritative deep dive into the economics behind the cost of making a LEGO brick, including material costs, manufacturing precision, supply chain complexities, and the company’s ambitious sustainability investments. Understanding this not only sheds light on the price you pay in stores but also highlights the innovations shaping the future of this beloved toy.

Within this post, I’ll break down the key factors that influence the cost to produce LEGO bricks, from raw materials and molding precision to energy consumption and labor. I'll also share how LEGO’s newest factories, such as the state-of-the-art facility opened in Vietnam in 2025, shape production costs with cutting-edge technology and sustainability initiatives. Whether you’re a LEGO enthusiast, a business student, or simply a curious consumer, this detailed exploration will give you a well-rounded, expert look at what goes into the cost structure behind every LEGO piece.

Understanding LEGO Brick Production: An Overview

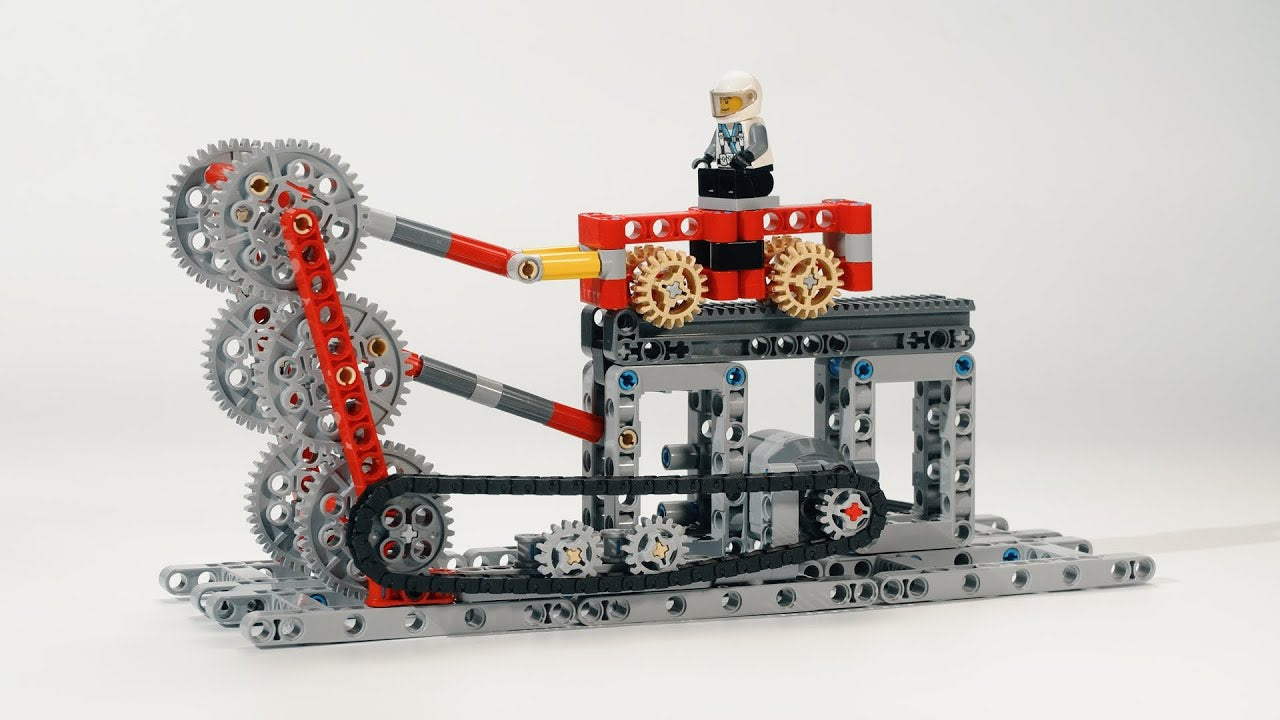

Before delving into cost specifics, it’s important to understand how LEGO bricks are produced at an industrial level. LEGO bricks are manufactured using high-precision injection molding processes that ensure each piece fits perfectly with others—this requires tolerances as tight as 1/10th the thickness of a human hair. The raw material for these bricks is primarily Acrylonitrile Butadiene Styrene (ABS), a durable type of plastic that provides long-lasting quality and vibrant colors.

LEGO’s production is carried out at multiple factories worldwide, with a significant focus on automated, highly efficient machinery and sustainable energy use. The newest and most advanced facility, LEGO Manufacturing Vietnam, opened in early 2025 with a $1 billion investment to support sustainable, large-scale production closer to the Asia-Pacific market.

Raw Material Costs: Plastic and Beyond

The largest component of the cost to make a LEGO brick is the raw plastic material. Traditionally, LEGO bricks have been made from petroleum-based ABS plastic. The company, however, is shifting towards renewable and more sustainable plastics, which come at a premium. According to recent reports, LEGO is paying up to 70% more for certified renewable resin compared to traditional oil-based plastics.

This shift reflects LEGO’s commitment to reducing its environmental footprint, with substantial investments—over $1.4 billion planned through 2025—aimed at making bricks from sustainable materials. While these eco-friendly materials increase production costs initially, LEGO views it as a necessary part of their long-term business strategy.

Precision Manufacturing: Technology and Labor

Each LEGO brick is produced with exceptional precision to maintain uniform size and clutch power (the ability to snap together firmly). This level of quality mandates high-tech molding equipment and strict quality control processes, significantly influencing manufacturing expenses.

LEGO’s global factories employ automated molding machines and quality checks that produce millions of bricks daily with less human intervention, reducing labor costs but increasing capital expenditure on machinery. The Vietnam factory, for instance, spans 44 hectares with advanced technology and is designed for zero waste and energy-efficient operations, enhancing cost efficiency over time.

Energy and Sustainability Investments

Energy costs are a significant consideration in LEGO’s production budget. The company’s factories are notable for their commitment to renewable energy use—LEGO Manufacturing Vietnam is powered largely by rooftop solar panels and an adjacent energy centre that includes battery storage solutions. This transition to renewable energy aligns with LEGO’s goal for net-zero emissions in production and reflects a rising trend of sustainability-related capital investments being factored into manufacturing costs.

While the upfront costs for installing solar and energy-efficient technologies are substantial, these efforts decrease long-term energy costs and environmental impact, stabilizing overall production expenses with a leaner carbon footprint.

Logistics and Supply Chain Factors

Manufacturing cost is only part of the total cost of producing LEGO bricks. Logistics—including warehousing, transportation, and distribution—also play a vital role. Following a supply chain overhaul, LEGO reportedly saved $67 million in logistics over three years, underscoring the importance of efficient logistics in cost management.

By operating factories closer to key markets, such as the Asia-Pacific region via the new Vietnam facility, LEGO reduces transportation distances and costs, which improves economic and environmental results.

Approximate Cost per LEGO Brick

Estimating the exact cost to make a single LEGO brick is challenging because of the variety of brick types, molds, sizes, and the scale of production. However, industry estimates and economic modeling suggest that the cost to manufacture a basic LEGO brick can be roughly around 3 to 7 cents USD per piece in raw and direct production costs. This includes plastic, molding, labor, and energy, but excludes overhead, R&D, marketing, and distribution.

Given LEGO’s recent investments in renewable plastics (which cost up to 70% more than traditional plastics), plus state-of-the-art factory technologies, this figure is likely on the higher end or rising slightly in 2025. However, the company’s efficiencies through automation and sustainable practices help to balance overall costs.

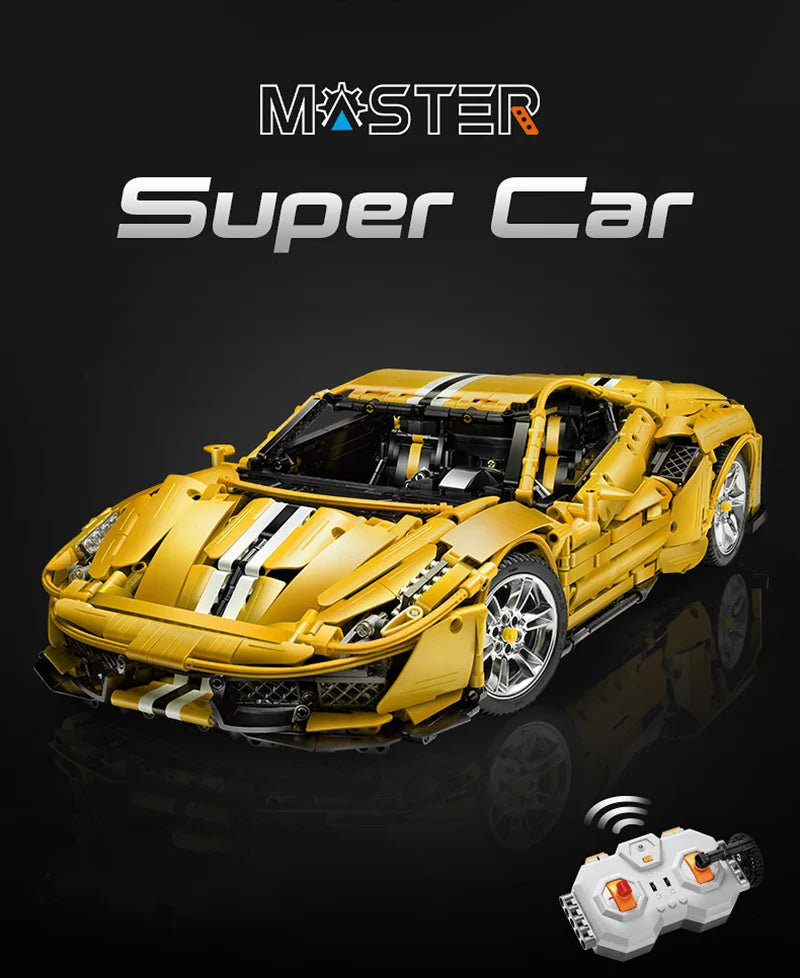

The Bigger Picture: From Cost to Retail Price

While it might cost just a few cents to make a LEGO brick, the retail price reflects much more—including design, creativity licensing (e.g., Star Wars, Harry Potter sets), packaging, marketing, and global distribution. For example, a small LEGO set with 100 pieces may sell for $15–$30, a significant markup over raw production costs, driven by brand value and consumer demand.

Conclusion: The Cost of Crafting Creativity

To sum up, making a LEGO brick involves a complex interplay of materials science, precision manufacturing, sustainability initiatives, and smart supply chain management. With raw plastic costs influenced by a shift to renewable materials, automated factories employing the latest technology, and energy-smart operations, the cost landscape in 2025 reflects both LEGO’s commitment to quality and sustainability.

Understanding these factors not only reveals why LEGO bricks cost what they do but also highlights LEGO’s role as a pioneer in responsible manufacturing—making every brick a small marvel of engineering and environmental consciousness that fuels creativity around the world.