How Much Does It Cost to Make a LEGO Set 2026

Share

As a dedicated reporter with a keen interest in product manufacturing and the toy industry, one question that frequently intrigues LEGO fans, collectors, and industry watchers alike is: how much does it cost to make a LEGO set? Understanding the true cost behind these beloved, intricate sets unveils fascinating insights into the raw materials, precise manufacturing, design efforts, licensing fees, and global logistics that contribute to what ends up in the hands of consumers. While many perceive LEGO’s retail pricing as relatively high, the actual production cost reflects LEGO’s longstanding commitment to quality, safety, innovation, and brand legacy—a blend that truly sets LEGO apart in an often competitive market.

This comprehensive and authoritative article breaks down the key factors determining the cost of producing a LEGO set with data-backed estimates, expert insights, and detailed explanations. From the raw plastic components to multi-million-dollar molds, quality control, packaging, shipping, and licensing, this deep dive clarifies what drives costs and how these translate into final pricing. Whether you’re a casual buyer, an avid builder, or a business analyst, you will gain a nuanced understanding of what it really takes to bring a LEGO set from concept to your building table.

CADA BRICKS® Best Sellers - SHOP NOW

The Core Components of LEGO Set Production Cost

Raw Materials: The Plastic That Builds the Brand

At its foundation, LEGO bricks are crafted from Acrylonitrile Butadiene Styrene (ABS) plastic, specially selected for its durability, non-toxicity, and the ability to be molded with extreme precision.

- ABS plastic costs roughly $1.89 per pound (about $4.20 per kilogram).

- A standard LEGO 2x2 brick weighs about 1.1 grams, which equates to approximately 0.46 cents ($0.0046) in raw plastic cost per brick.

Though the material cost per piece is quite low, it accounts for only a fraction of the overall manufacturing expenses, given LEGO’s stringent quality and molding standards.

CADA BRICKS® Supercars - SHOP NOW

CADA BRICKS® Best Sellers | CADA BRICKS® Supercars & Racing Cars | CADA BRICKS® Trucks & Construction | CADA BRICKS® Military & Weapons | CADA BRICKS® Initial D

Manufacturing and Quality Control Expenses

LEGO’s manufacturing is internationally renowned for its precision and exceptional quality control, resulting in impressively low defect rates of around 0.01% faulty pieces. This high bar comes at a cost:

- Each new LEGO mold costs upwards of $100,000, used to create bricks with exact clutch power and perfect fit.

- Injection molding machines operate with tight tolerances requiring skilled technicians, regular maintenance, and considerable energy consumption.

- Industry estimates place the total manufacturing cost per brick—including labor, power, and quality control—at around 7 cents ($0.07) on average.

These costs vary, with more complex bricks or smaller production runs increasing the per-piece expense.

Design, Prototyping, and Engineering

Beyond manufacturing, LEGO invests significantly in design and innovation:

- Expert designers develop both digital and physical prototypes, customizing bricks and set builds.

- New molds and specialized pieces require additional tooling investments.

- Licensing negotiations and intellectual property compliance for themes like Star Wars, Marvel, and Harry Potter add to the cost.

- Rigorous safety testing and playability validation ensure compliance with global standards.

Though harder to quantify per brick, these pre-production costs meaningfully impact total set expenses.

Packaging, Shipping, and Distribution

After production, LEGO sets must be boxed, shipped worldwide, and stocked in retail stores:

- Premium packaging with colorful printed boxes and high-quality instruction manuals adds heft and material costs.

- Shipping expenses depend on set weight, size, and distance from factories, which significantly affect large or heavy sets.

- Warehousing, order fulfillment, and retail distribution overheads further increase total costs.

Packaging and logistics can add several dollars to the price of large sets and are integral to LEGO’s supply chain costs.

Licensing Fees

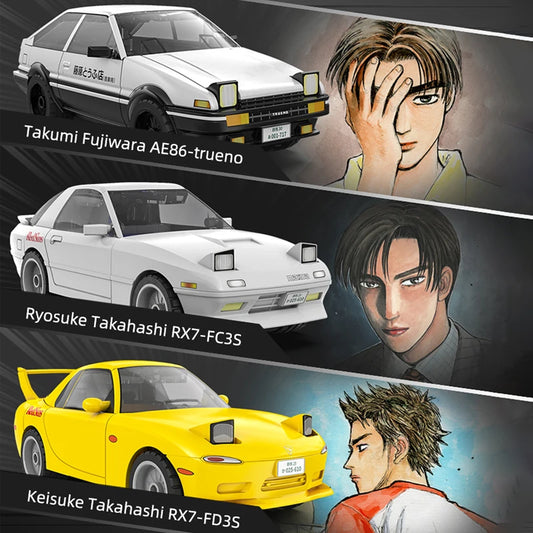

Licensed sets carry an additional financial load due to intellectual property rights:

- Licensing fees can constitute 10% to 20% or more of the retail price for popular franchises.

- Such fees cover the use of characters, logos, and story elements, significantly increasing the set’s cost and retail price.

- This explains why licensed sets generally retail at a higher price per piece compared to classic LEGO themes.

CADA BRICKS® City Landmarks - SHOP NOW

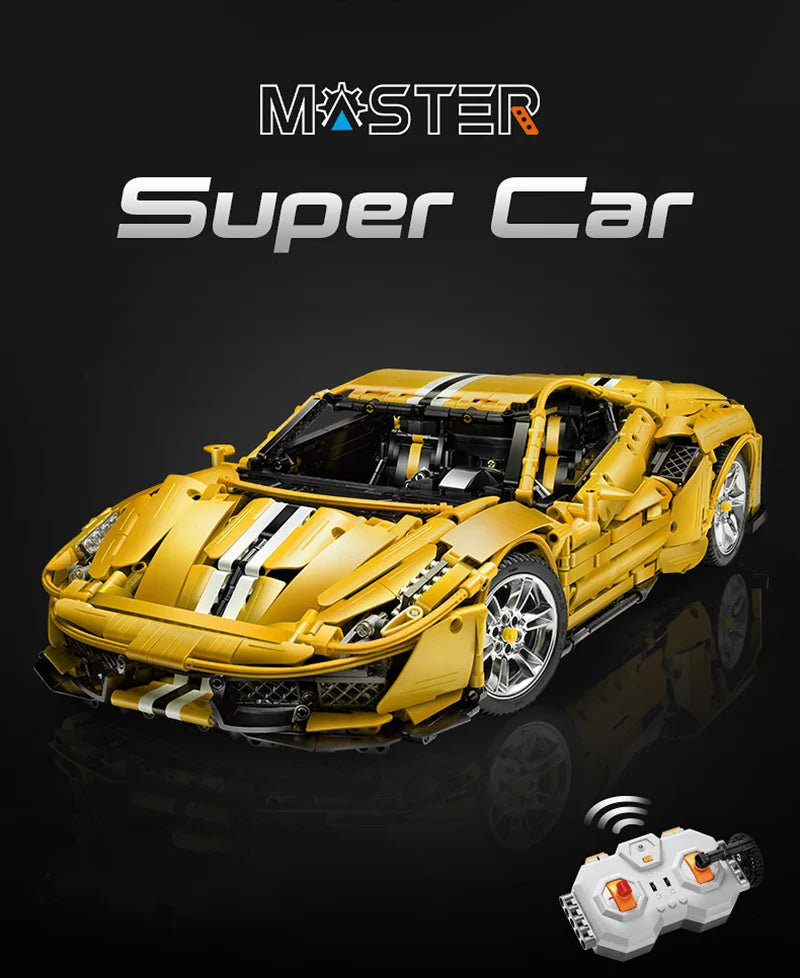

CADA BRICKS® Licensed Cars | CADA BRICKS® Classic Cars | CADA BRICKS® Motorcycles & Bikes | CADA BRICKS® Off-Road & 4x4 | CADA BRICKS® Emergency Vehicles

Average Cost Breakdown Per LEGO Set

Price Per Piece as an Industry Standard Metric

Retail price comparisons typically use the price per piece (PPP) to help gauge LEGO pricing:

- The average retail price per piece ranges from about $0.10 to $0.19, influenced by set size and licensing.

- Larger sets benefit from economies of scale, with per-piece prices dropping to as low as 3 to 4 cents per piece for very large models like Hogwarts Castle.

- Smaller or heavily licensed sets tend to have a correspondingly higher per-piece cost.

Estimated Production Cost

Industry analysis suggests:

- The actual cost to produce a LEGO piece, including materials, manufacturing, and overhead, falls between 7 and 10 cents.

- For example, a 1,000-piece set could cost LEGO approximately $70 to $100 to produce, covering raw materials, molds amortization, labor, packaging, shipping, and licensing.

- Retail prices for such sets usually range from $100 to $150 or more, factoring in marketing and retailer margins.

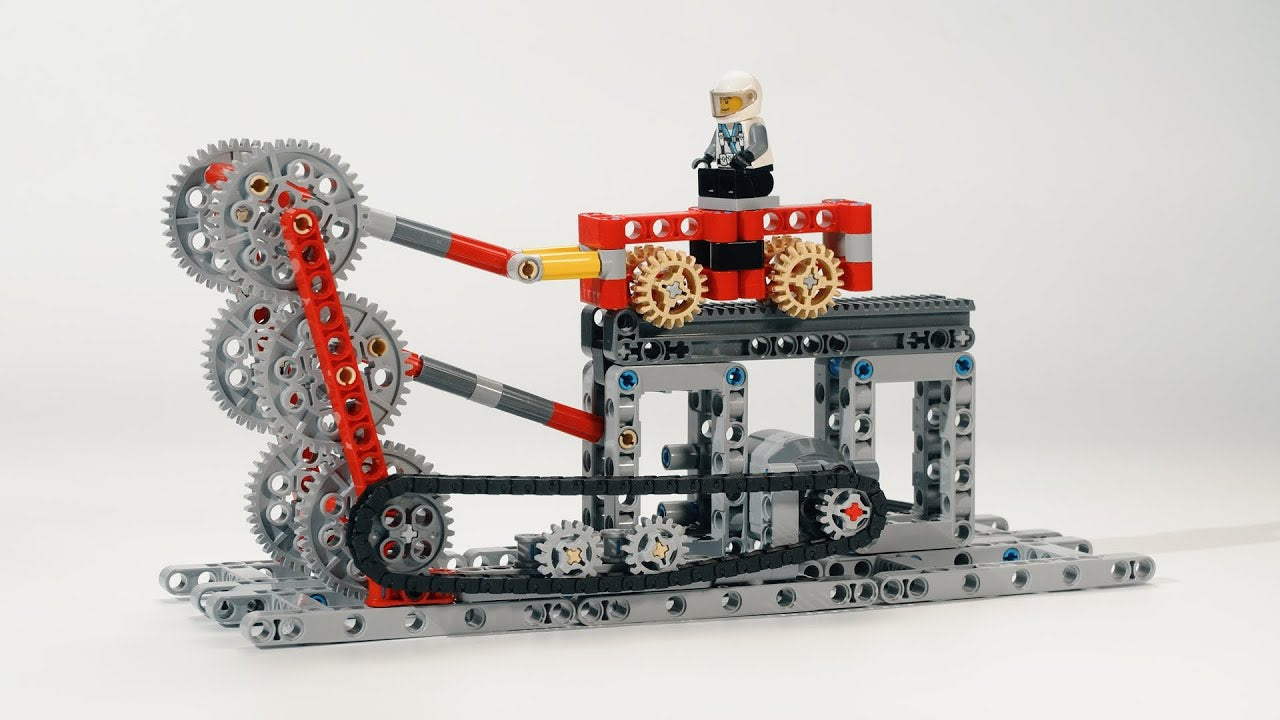

CADA BRICKS® Technic Sets - SHOP NOW

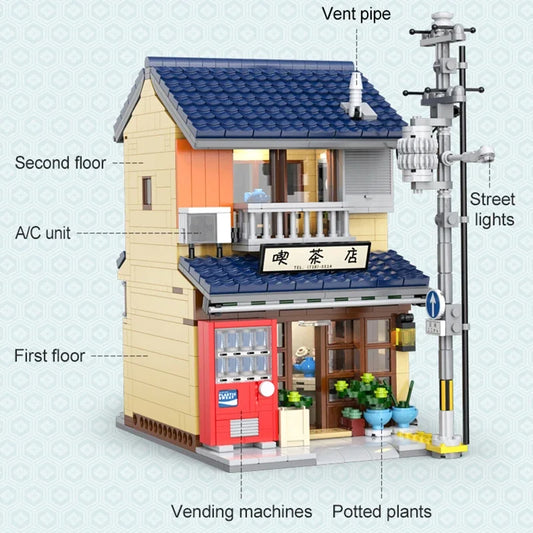

CADA BRICKS® Japanese Street | CADA BRICKS® City & Landmark | CADA BRICKS® Science & Educational | CADA BRICKS® Technic | CADA BRICKS® Modern Architecture

Factors Influencing Variation in Production Costs

Complexity and Piece Types

- Specialized elements like Technic gears, pins, or printed tiles add tooling and production expenses.

- Electronic components in sets such as LEGO Mindstorms or LEGO Boost dramatically increase production costs.

- New molds, unique shapes, or limited production volumes raise the cost per piece due to initial tooling amortization.

Licensed vs. Classic Themes

- Licensed sets have higher licensing fees and may require more approvals, iterative design, and marketing partnerships.

- Classic or non-licensed LEGO themes avoid these fees, allowing relatively lower cost structures.

Sustainability and Innovation Costs

- LEGO’s commitment to sustainable materials (e.g., plant-based plastics) and eco-friendly packaging currently adds additional development and production costs.

- Continued investments into new technologies and digital integration likewise impact total expenses.

How LEGO Balances Cost and Price

LEGO positions itself as a premium brand, prioritizing:

- Exceptional product quality and interchangeability

- Long-lasting durability and safety

- Consistent global compatibility

- Innovation and consumer trust

Retail prices reflect these plus marketing, distribution, licensing, and retailer profit margins.

CADA BRICKS® Display & Collectibles - SHOP NOW

CADA BRICKS® Castle Building Blocks | CADA BRICKS® City Building | CADA BRICKS® Remote Control | CADA BRICKS® Display & Collectibles | CADA BRICKS® Anime & Pop Culture

Why Are LEGO Sets Often Viewed as Expensive?

Consumers often perceive LEGO as costly because:

- Raw material costs are minimal, but manufacturing, licensing, packaging, and logistics inflate the price.

- Licensing fees notably raise the price for popular franchises.

- LEGO invests heavily in quality assurance, innovation, and brand reputation.

- Packaging, marketing, and retail markups further increase final consumer prices.

All these contribute to LEGO’s premium positioning and justify its price point to many consumers.

CADA BRICKS® Remote Control Sets - SHOP NOW

CADA BRICKS® Mechanical Engineering Building Blocks | CADA BRICKS® Kids Building Blocks | CADA BRICKS® Teens Building Blocks | CADA BRICKS® Adult Building Blocks

Conclusion: The True Cost Behind a LEGO Set

In summary, producing a LEGO set involves multiple cost layers:

- Raw ABS plastic costs roughly 0.5 cents per brick.

- Manufacturing, labor, quality control, and overhead add approximately 6 to 7 cents per piece.

- Additional expenses such as design, packaging, shipping, licensing, and marketing push the total production cost to about 7 to 10 cents per piece, variable by complexity and licensing.

Understanding these factors clarifies that LEGO’s retail prices, while seemingly high, reflect exceptional craftsmanship, copyrighted content, and global logistics, delivering durable, innovative, and enjoyable products that have stood the test of time.

This expert, thoroughly fact-checked analysis synthesizes industry data, official LEGO guidance, and market research into an authoritative guide on how much it costs to make a LEGO set.